fineboatplans.blogspot.com

fineboatplans.blogspot.com Opening: The Allure of DIY Boat Building

Building your own aluminum rib boat is a rewarding project that combines engineering, craftsmanship, and the thrill of creating something with your own hands. This guide provides a step-by-step walkthrough, assuming you have basic metalworking skills and a solid understanding of boat design principles. Remember, safety is paramount. Always wear appropriate safety gear and consult with experienced professionals when needed.

Step 1: Planning and Preparation

Understanding Your Needs Determine the intended use of the boat: fishing, leisure cruising, or a combination. Decide on the desired size and capacity. Consider the number of passengers and typical load. Research local regulations and building codes related to boat construction.

Sourcing Plans and Materials Obtain a detailed set of aluminum rib boat plans. Numerous online resources offer plans, often with different hull designs and features. Verify the credentials and reviews of the plan provider. Create a detailed materials list based on the plans. This will include aluminum sheets and extrusions, welding wire, rivets, adhesives, and hardware. Source high-quality marine-grade aluminum suitable for boat construction. Alloys like 5052 or 6061 are commonly used for their corrosion resistance and weldability.

Tools and Equipment Welder (TIG or MIG welding is recommended for aluminum) Metal cutting tools (plasma cutter, angle grinder with cutting discs, or metal shear) Drill and drill bits Riveter Clamps and jigs Measuring tools (tape measure, level, protractor) Safety gear (welding helmet, gloves, safety glasses, ear protection)

Step 2: Cutting and Shaping the Aluminum

Cutting the Hull Panels Carefully transfer the dimensions from the boat plans onto the aluminum sheets. Use accurate measuring and marking techniques to ensure precise cuts. Use a plasma cutter, angle grinder, or metal shear to cut the hull panels according to the marked lines. Exercise caution to avoid warping or damaging the aluminum. Deburr the edges of the cut panels to remove sharp edges and improve welding.

Forming the Hull Shape The plans will indicate how to bend or form the aluminum panels to create the desired hull shape. This may involve using rollers, presses, or manual bending techniques. Use clamps and jigs to hold the panels in the correct shape while welding. Ensure proper alignment and symmetry throughout the forming process.

Constructing the Ribs Cut the aluminum extrusions for the ribs according to the plans. Bend or shape the ribs to match the hull curvature. This may require specialized bending tools. Attach the ribs to the hull panels using welding or riveting. Ensure the ribs are evenly spaced and securely fastened.

Step 3: Welding and Joining

Welding the Hull Seams Clean the aluminum surfaces thoroughly before welding to remove any dirt, grease, or oxides. Use a TIG or MIG welder with appropriate settings for aluminum welding. Weld the hull seams together, creating a watertight seal. Use proper welding techniques to minimize distortion and ensure strong, durable welds. Grind down the welds for a smooth finish.

Attaching the Transom The transom is the rear of the boat where the motor will be mounted. Cut and shape the transom panel according to the plans. Weld or rivet the transom to the hull, ensuring a strong and watertight connection. Reinforce the transom with additional supports if necessary, especially for larger engines.

Installing the Floor Cut and shape the aluminum floor panels. Consider adding non-slip texture to the floor surface. Weld or rivet the floor panels to the ribs and hull, creating a solid and level surface. Ensure proper drainage by incorporating drain holes or channels in the floor.

Step 4: Finishing and Outfitting

Leak Testing Before painting or adding other components, test the boat for leaks. Fill the hull with water and check for any signs of leakage. Repair any leaks by re-welding or sealing the affected areas.

Painting and Coating Prepare the aluminum surface for painting by cleaning and etching it. Apply a marine-grade primer and paint to protect the aluminum from corrosion and enhance its appearance. Consider applying a non-slip coating to the deck and other areas for safety.

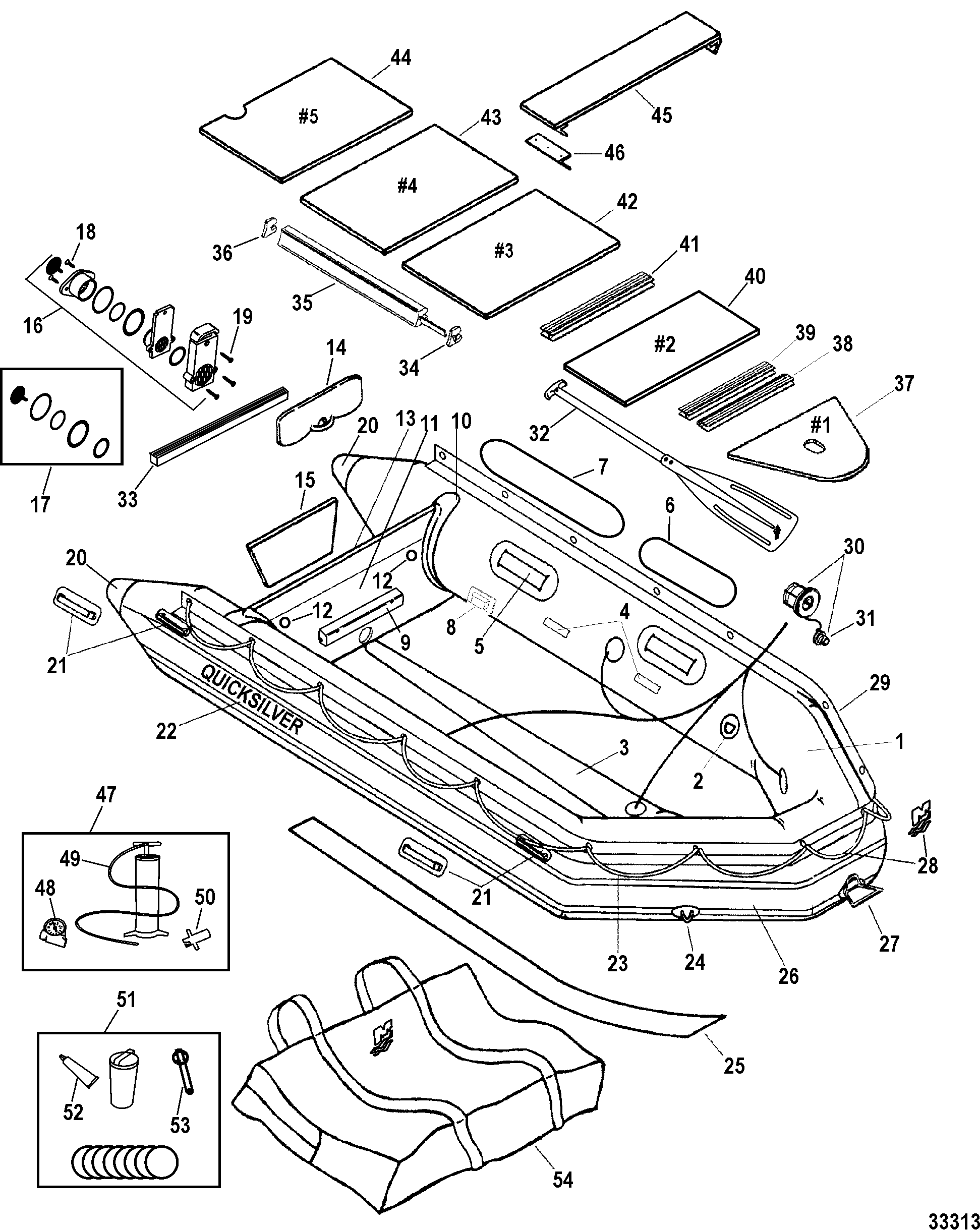

Adding Hardware and Accessories Install hardware such as cleats, railings, seats, steering system, and navigation lights. Install the engine and related components, following the manufacturer's instructions. Add any other desired accessories, such as fishing rod holders, storage compartments, or electronic equipment.

Conclusion: Enjoying Your Creation

Building your own aluminum rib boat is a significant undertaking, but the satisfaction of completing the project and enjoying your handcrafted vessel is immense. Remember to conduct thorough safety checks before each voyage, adhere to all applicable boating regulations, and take pride in your accomplishment. Happy boating!

Aluminium Rib Boat Plans

Aluminium Rib Boat Plans

fineboatplans.blogspot.com

fineboatplans.blogspot.com Aluminium Rib Boat Plans

tempatboat.blogspot.com

tempatboat.blogspot.com

0 komentar:

Posting Komentar